Aluminium Pistons and rods are important parts of engines, but they don’t necessarily add power or improve performance. They only affect things such as fuel efficiency and emissions. What exactly are pistons and rods, anyway? Hyundai iLoad Engines will explain it.

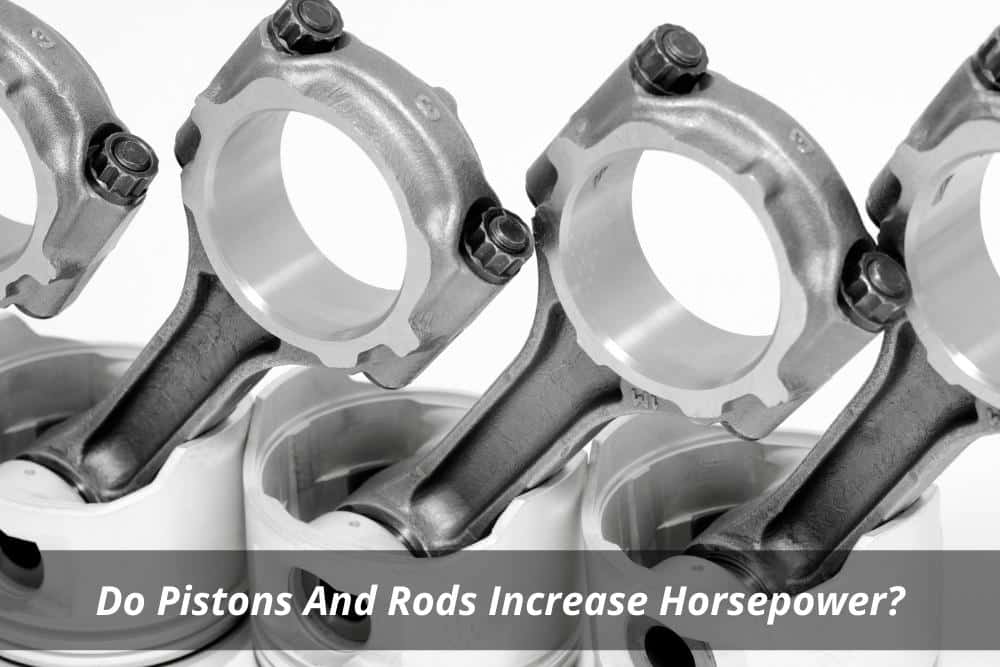

Pistons and Rods

A piston is the part of an internal combustion engine (ICE) that moves back and forth during each cycle of operation. The piston compresses the air/fuel mixture into the cylinder, ignites it, and then forces it out through the exhaust valve.

Rods

A rod connects the crankshaft to the piston to suit. A rod has two ends: the connecting rod cap at the top and the crank pin at the bottom. Rods transfer the force from the crankshaft directly to the piston.

What are the Benefits of Pistons and Rods?

- Piston rings allow for a smaller gap between the piston head and the wall of the cylinder than would be possible with the use of other types of seals. This allows for more efficient cooling of the engine.

- By transferring the forces of rotation, the rods reduce stresses on the crankshaft bearings.

- Pistons and rods can have different shapes or sizes depending on their application. For example, some engines have large-diameter pistons that run hotter than smaller-diameter pistons do.

- In certain situations, the weight of the rods may help stabilize the engine.

Why don’t I see them in Ice Cars?

Many ICE cars built in the past were equipped with small-diameter, non-oversize pistons because many of them didn’t need much power. Today’s higher-performance vehicles often have larger-diameter, oversize pistons. These pistons push harder against the walls of the cylinders, which increases the volume of compression per revolution of the engine.

The size of the piston also affects how efficiently the oil circulates throughout the engine. To avoid overheating, the piston must fit within the specified dimensions. If the piston is too big, it will not compress enough air and fuel; if it is too small, there won’t be enough room to circulate the oil properly.

How does the Engine Work?

An engine uses four basic components to convert chemical energy into mechanical work. The first component is a chamber called the “combustion zone.” Combustion occurs when a spark causes a flame to ignite the air/fuel mixture inside this chamber.

When the flame burns completely, the explosive expansion of gases pushes the piston downward and drives a crankshaft attached to the piston. After each explosion, the burned gases pass up through the exhaust pipe and leave the car.

The Cycle of Operation

The second component is what makes the engine turn. It consists of a series of valves that open and close to direct the flow of air and fuel through the engine. The third component is the ignition system. This includes various devices that control the timing and rate of ignition.

Finally, a device known as a governor controls the amount of gas entering the engine. Through all these mechanisms, the engine works together to produce the desired level of torque and speed at any given time.

Piston Composition

Most pistons and rods are made from cast iron and nickel steel. Cast iron is durable but heavy. Nickel steel is lighter, but it wears down quickly. Most modern engines contain alloy pistons.

Aluminium is light, strong and heat resistant. Although it is not very wear-resistant, it is almost always used in conjunction with liners made from high-strength carbon steel.

A new piston is usually composed of three parts—the crown, skirt and ring pack. The crown is where most of the metal of the piston comes from. The skirt helps support the crown, while the ring pack holds the rings that act like tiny gears in the cylinder wall.

Rings that Are Like Gas Turbines

Rings are placed around the edge of the piston head. They keep the oil that lubricates the engine from escaping between the side of the piston and the cylinder wall. Each ring has two flanges: an inner one that slides along the wall of the cylinder, and an outer one that keeps the rings from floating away from the piston face during combustion.

Ring Pack and Crankshaft

In order for the piston to move smoothly back and forth, it must slide freely across the top end of a rod. This part of the piston is called the crown or skirt, depending on whether the bottom (or “crown”) of the piston faces forward or backward.

Although the piston doesn’t actually rotate, its movement is guided by a connecting rod. A crank is attached to the ends of the connecting rod. Inside the crankcase is a hollow shaft that fits snugly around the crankshaft. One end of the shaft contains bearings where the drive belts attach.

In some engines, the connecting rod is contained entirely within the crankcase. In others, the connecting rod protrudes outside the case and attaches directly to the crankshaft or flywheel.

Timing Valve Placement

One of the last items we’ll discuss is the placement of timing valves. Timing valves are designed to ensure that the right amounts of gasoline and air enter the engine at the appropriate times.

There are three main types of timing valves: intake, exhaust and balance. All have their own advantages and disadvantages. For example, the intake valve allows more oxygen into the engine and thus increases power; however, it also allows more gasoline out of the tank, which can lead to problems if there’s too much fuel in the carburettor.

On the other hand, the exhaust valve lets less gasoline escape, so it reduces pollution. But because it takes longer than the intake valve for the gasoline to burn, it produces less power. Finally, the balance valve ensures that enough gas enters the engine when the cylinders are cold and that too little gas flows after the engine warms up.

The best option depends on how you plan to use your boat. If you want a powerful engine that will cruise happily on all fours, choose an intake/exhaust combination. If you’re going to be racing, go with the balance system.

The Basic Of Engine Rebuilding

If your engine needs replacing, you may not know what type of engine it is. An engine number plate is located on each end of the block. It will look something like this: “1K-3P” or “2M-4N.” These numbers indicate the displacement of the engine and tell you a bit about the size and construction of the blocks.

Once you’ve determined what kind of engine you need, contact a local repair shop to find out what they think your engine looks like. Ask them to give you a schematic drawing of your engine so you can match it up with the drawings of our various engines.

Engine Removal & Installation

Before removing your old engine, check the crankshaft pulley first. There should be no loose material around the teeth of the pulley. If there is, remove it. Some engines have a small metal tab on the front of the pulley that holds the belt in place.

With a pair of pliers, bend the tab down slightly to release the belt. Remove the belt before you disassemble the rest of the pulleys.

After the old engine is removed, you can begin inspecting the old parts. Inspect each component for damage or wear. You can do this by removing any seals that might be worn or damaged.

When doing so, be careful not to break anything new. Once you’ve examined everything thoroughly, clean off the surface with compressed air. This will help prevent rust from forming on the part.

The next step is to remove the cylinder head, cam cover, rocker arms, lifters, pushrods, and springs. Clean these components with solvent. Never use alcohol or acetone as solvents; instead, use mineral spirits. Mineral spirits evaporate very slowly, making them safe to work with.

After cleaning the parts, inspect them. Any cracks or tears should be repaired immediately. Cracks weaken engine materials. Make sure that all gaskets are intact.

Look for signs of water leakage. If you find any leaks, tighten all bolts and replace any rubber sealant that has degraded.

When assembling the new engine, follow the same procedure used to assemble the old one, but make adjustments where necessary. Be especially mindful of installing the cams properly and keeping smooth bearings free of dirt.

If the engine requires a new crankcase, ask the mechanic to install it for you. An excellent way to do this is to locate a set of replacement pistons at the same time you order your engine. This will save you some money since the cost of the pistons and rods is included in the price of the machine.

The final step is to reattach the accessory drive belts to the engine. To do this, slide the rings over the ends of the shaft until they click into place. Secure the belts with a suitable locking device such as a C-clamp.

Filling the Engine with Oil

For maximum performance, fill the engine with the highest quality extra virgin olive oil. After filling the cylinders, add several drops of dishwashing liquid to keep the mixture lubricated. Dishwashing liquids contain surfactants that act as detergents and emulsifiers.

They also absorb moisture from the air and thereby reduce sludge buildup inside the engine. Fill the carburettor with enough fuel to allow the vehicle to run smoothly when started.

CAUTION!

Never mix gasoline and diesel engine fuels. Both cause severe corrosion if mixed together.

Hyundais engine oil is designed specifically for the Hyundai ix35 2.0 DCI petrol engine found in the Hyundai ix35. It provides excellent protection against extreme temperatures and extreme pressure conditions. Oil level indicator

Check oil levels regularly. Oil should always be checked before starting the engine. The most accurate method involves using an oil dipstick.

Dipsticks come in many sizes and shapes. Most have markings indicating low, medium or full oil levels.

Hyundai iload engine oil is made up of four main elements: paraffin, naphthenic base, synthetic ester, and friction modifier. Paraffin (a type of wax) is the primary element in most conventional oils. It helps maintain oil viscosity and prevents metal surfaces from rusting.

Naphthenes and other compounds perform similar functions. The addition of synthetic esters increases the ability of the oil to withstand extreme heat. Friction modifiers help prevent wear on engine components.